VEL HardTech Series

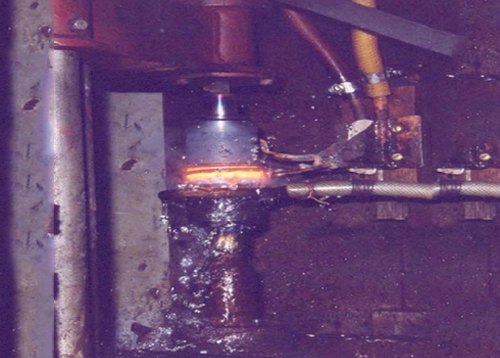

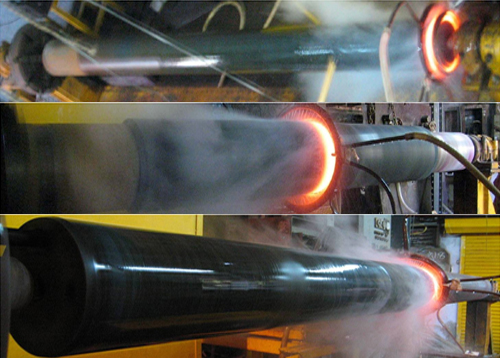

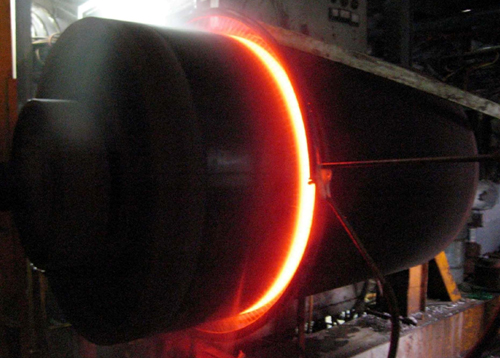

The VEL HardTech series represents cutting-edge induction hardening, annealing, and tempering systems tailored to meet the evolving needs of the heat treatment industry.

We offer complete turnkey solutions that include an advanced Induction Power Source, CNC/PLC control automation, high-frequency transformer, and custom-designed coils tailored for specific jobs. Our solutions also feature job-specific scanning (horizontal or vertical), single-shot fixtures, and rotary or indexing tables. They seamlessly integrate with semi or fully automated job loading and unloading facilities, ensuring that the system fulfills your hardening requirements effectively.

Related Services:

Induction Hardening Machine, Induction Hardening Equipment,CNC Induction Hardening Machine,Crankshaft Induction Hardening Machine,Portable & Vertical Induction Hardening Machine.

Standard Features

- Manual and automated program settings with multiple pre-programmed recipes.

- Intuitive touch panel interface with comprehensive process monitoring features.

- Quick connect coil system facilitates easy replacement of induction coils.

- Efficient load/unload and part centering system for manual or automated operations.

- Designed for in-line integration, ensuring short lead times and seamless workflow.

- Reliable mechanical solutions ensure high system availability and productivity.

- Precise process control leads to excellent results and increased productivity.

- Energy-efficient power supply unit (>95% efficiency) reduces energy costs.

- Flexible design accommodates a wide range of part sizes for versatility.

- Modular unit for easy servicing and maintenance, minimizing downtime.

Our Machines Supplied

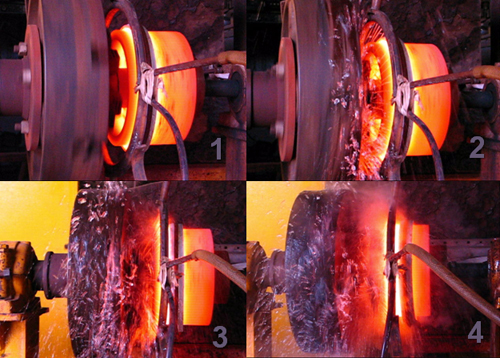

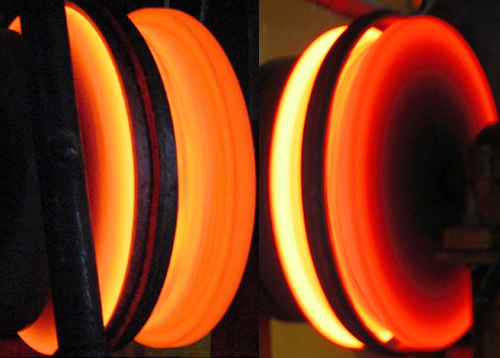

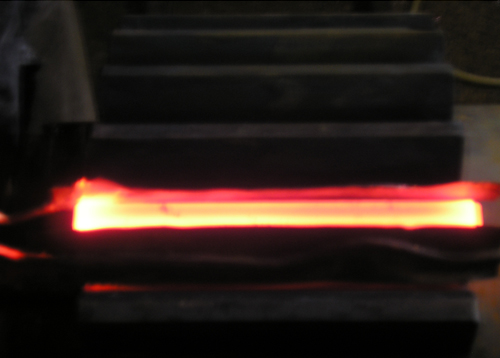

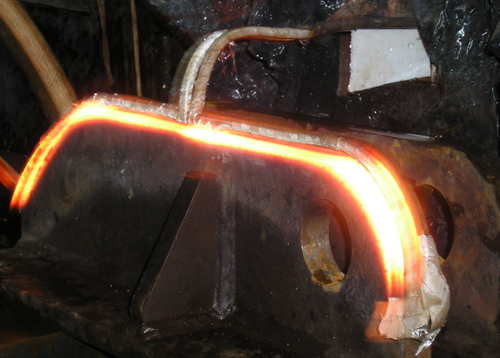

The Induction Hardening System (VEL/IH Series) is specially designed for Induction Hardening of components on turnkey basis complete with>Induction Power Source >CNC/PLC based servo motor driven Vertical/Horizontal Scanner > Water circulating & Cooling system and Quenching system >Semi-Automated/ Fully Automated job loading/unloading facility (optional)

| TYPE | VEL/IH50 | VEL/IH100 | VEL/IH200 | VEL/IH400 |

| Inverter | IGBT based Inverter | |||

| Converter | Thyristor based Full bridge Rectifier | |||

| IncomingVoltage | 415V,3phase,50Hz,4wire | |||

| InputFeederRating | 100 amps | 200 amps | 400 amps | 800 amps |

| OutputPower | 50kW | 100kW | 200kW | 400kW |

| OutputFrequency | 1-100kHz(asperjobrequirement) | |||

| OutputVoltage | 0–400V | 0–400V | 0–400V | 0–400V |

| Max.OutputCurrent | 1000Amax | 2000Amax | 4000Amax | 8000Amax |

Download Catalogue

| Accessories | Description & Features |

| Job Handling Fixture | 1)Vertical Scanner: CNC/PLC based servo motor driven Horizontal Scanner of 20mm to 2000mm length to provide precision control of scan speed 0-100mm/sec & position with job rotation facility with varying rotation speed of 0-300rpm. 2) Horizontal Scanner: 3) Single Shot Fixture : With or without job rotation 4) Indexing / Rotary Table: 2-4stationsforhigherproductionratewith/withoutjobrotation 5) Rotary Scanners: Forjobssuchaspulley,slewrings,ropedrumetc. |

| Cooling System | 1) Refrigerant Chiller Unit

2) Cooling Tower with plate – type heat exchanger |