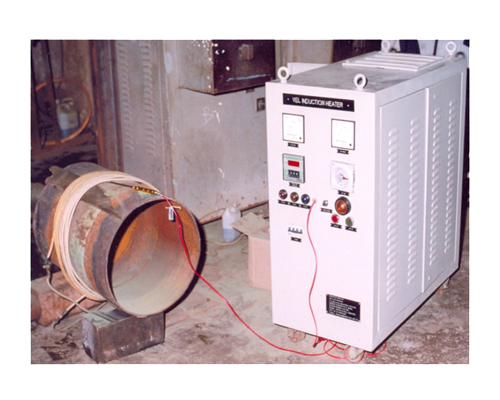

VEL PH/PW Series

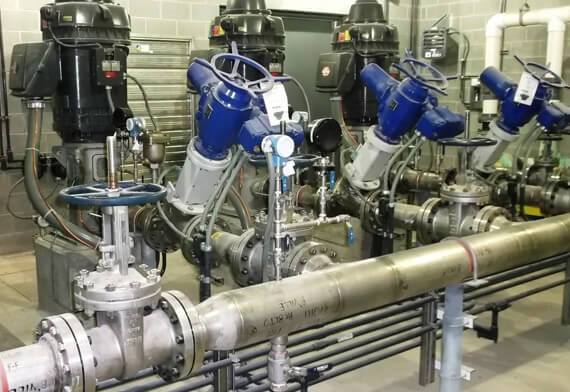

The VEL PH/PW series provides a highly versatile tool for preheating, stress relieving, hydrogen bake out and post weld heat treat in a variety of pipe diameters and flat plate.

Standard Features

- Designed for continuous heating operation

- Equipped with rugged heavy duty components to tolerate harsh working conditions

- Very Compact and portable (could be easily mounted on any trailer / trolley & moved by forklift / crane)

- All safety trips / interlocks incorporated including sensing the temperature of critical power components of the equipment

- Efficiency of the power source is better than 95%

- Low Voltage design makes it very safe to use at site

- Inductors are specifically designed keeping in mind ease of operation

- Thermal Profile Controller, Data Logger & Paper Chart Temperature Recorder is integrated as required.

- Provides uniform rapid heating in plate and pipe applications

- Reduces set-up time and time-to temperature

Our Machines Supplied

| TYPE | VEL/PH20 | VEL/PH40 | VEL/PW50 | VEL/PW100 | VEL/PW200 |

| Input Voltage | 220V, 1ɸ,50Hz | 415V, 3ɸ,50Hz | |||

| Output Power | 20kW | 40kW | 50kW | 100kW | 200kW |

| Temperature | 25-250°C | 25-1000°C | |||

| Application | Pre-Heating | Pre-Heating & Post Weld Heat Treatment | |||

| Pipe Dimensions | Ø150-500 x

3-16thick x 50-150mm bandwidth |

Ø400-1200 x

3-25 thick x 100-300 mm bandwidth |

Ø400-1200 x

3-25thick x 100-300mm bandwidth |

Ø400-1200 x

3-150thick x 100-400mm bandwidth |

Ø400-1800 x

3-300 thick x 150-600mm bandwidth |

| Cooling Coil | Air | Water | |||

| Heating Rate | —————————– 1-50⁰C/min—————————– | ||||

Note: Any Intermittent Power Shall Be Provided as Per Customer Requirement. We Also Provide Customised Solution for Specific Applications.

| Accessories | Description & Features |

| Digital Recorder |

The digital recorder is commonly used in stress relieving and critical preheat applications. The recorder stores temperature data based on time. It is not required to perform successful heating applications. |

| Post Weld Heat Treatment Blanket |

The blanket efficiently insulates and optimizes the coupling distance between the coil and the workpiece, safeguarding the liquid-cooled cable. Its fully enclosed, sewn design also reduces dust, creating a cleaner and more conducive work environment. |

| Thermocouple & its accessories | Directly welding thermocouples onto the heated part offers unparalleled accuracy in monitoring and controlling temperature during the heating process, making it the most precise method for recording temperature data.

|

| Switch Remote | Switch Remote

Control the heating process remotely using our wired rocker switch remote, allowing for easy start and stop functionality. The remote comes equipped with a 7-meter cable for added flexibility and convenience. |

| Air cooled wrap around coil |