What is Induction Shrink Fitting?

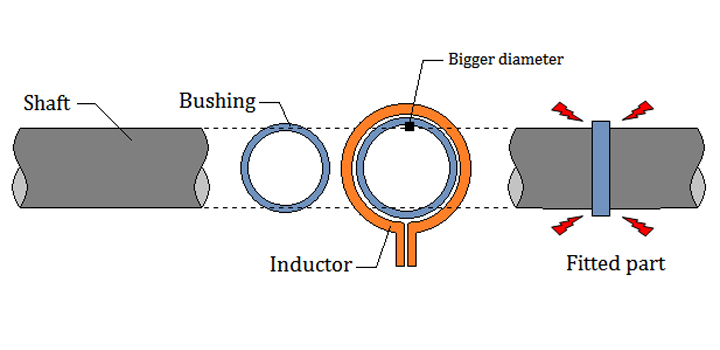

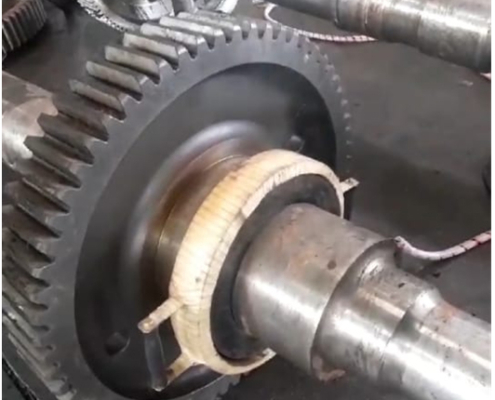

Induction shrink fitting is a specialized process used to assemble or disassemble components by utilizing the principle of thermal expansion and contraction. In this process, induction heating is employed to heat one component (usually the outer component or the housing) to a specific temperature, causing it to expand. Once the desired temperature is reached, the inner component (typically a shaft or a smaller part) is inserted or removed while the outer component is still hot.

As the outer component cools down, it contracts, creating a tight and secure fit with the inner component. The precise control over the heating process allows for accurate temperature management, ensuring that the components fit together seamlessly without damaging either part. This method is commonly used in various industries such as automotive, aerospace, manufacturing, and machinery for assembling gears, bearings, pulleys, shafts, and other components that require a precise and strong fit.

Services we provide

Induction Shrink Fitting of

- Roller Bearing,

- Inner Race,

- Bush,

- Sleeve,

- Pinions,

- Rotor Shaft Assemblies,

- Turbine blades,

- Pressure Tube in PHWR