A) Wet Fog Dust Suppression Systems

Atomization is designed to reduce the surface tension of the water droplets, while increasing the number of droplets in a given area and eliminating the need for the addition of surfactants or other additives. The low level of water added through the fog/mist systems – typically at 0.01% to 0.05% by weight of the material – generally will not degrade the performance of the material.

Single-Fluid Atomization

This system uses an ultra-fine stream of water pumped at high pressure through single-fluid atomizing nozzles. It does not require compressed air or an additional power source other than the electricity to run its pump. Single-fluid nozzles use hydraulic atomization to generate the mist. Water is forced under pressure through a small orifice that shatters the water droplets into microscopic particles. The energy created by the high-pressure is used to atomize the water droplets, rather than increase water velocity, thereby minimizing displaced air.

Features Of The Wet Fog Dust Suppression Systems:

- Fog systems provide highly effective dust capture combined with economical capital and operating costs.

- A well designed fogging system can provide excellent control of dust at the point of application without the need for chemical additives. Since fog systems only add water, they protect the integrity of the customer process.

- Total moisture addition to the bulk material can be realistically less than 0.1%. This makes fog suppression systems attractive in industries that cannot tolerate excess moisture, such as cement and lime production.

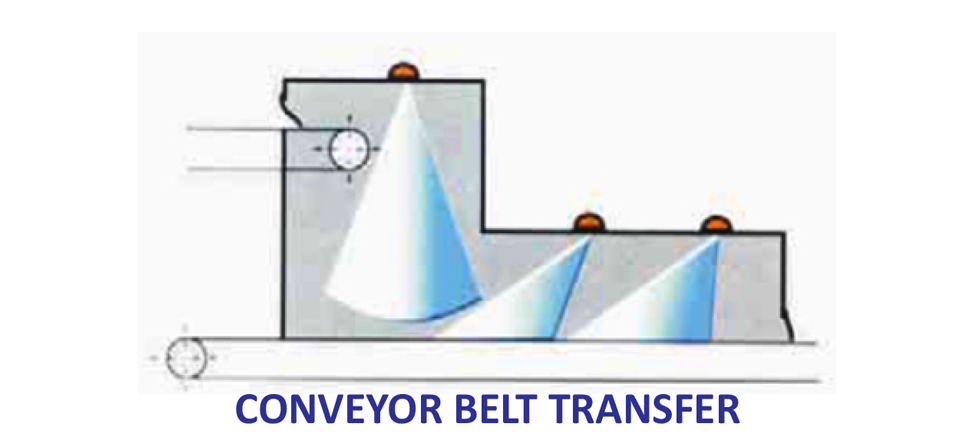

- For truly effective performance, fog dust suppression systems require tight enclosure of the transfer point that minimises turbulent, high-velocity air movement through the system.

- These systems consist of atomizing nozzles which produce a very fine mist droplets that float freely in the air and create fog. The spray pattern covers the particular area continuously so that the dust gets heavier and falls down.

Some of Our Installed Dust Suppression Systems

Industries Wise Application

Cement

Mining

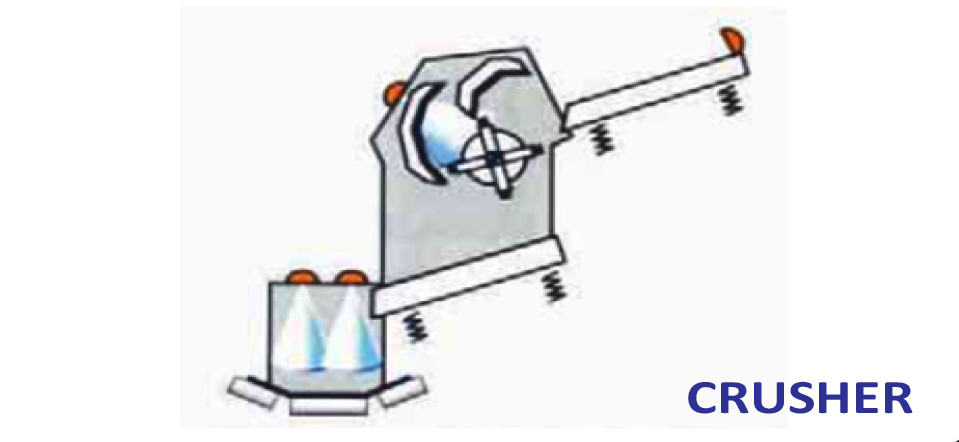

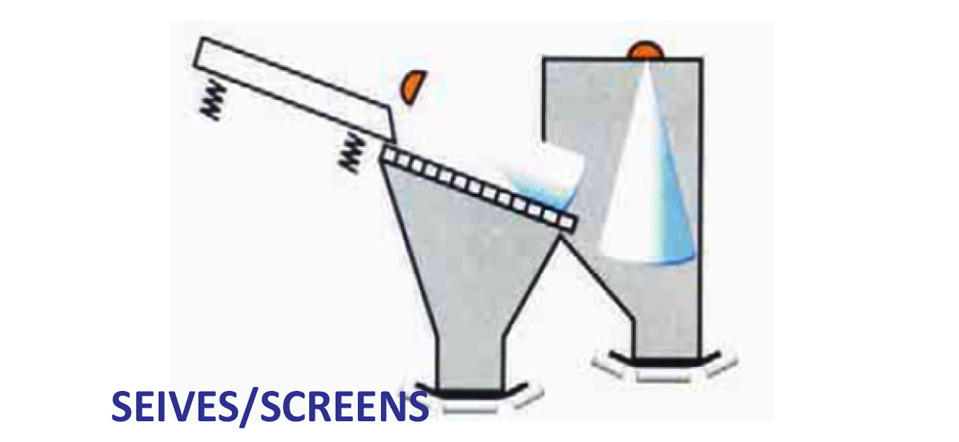

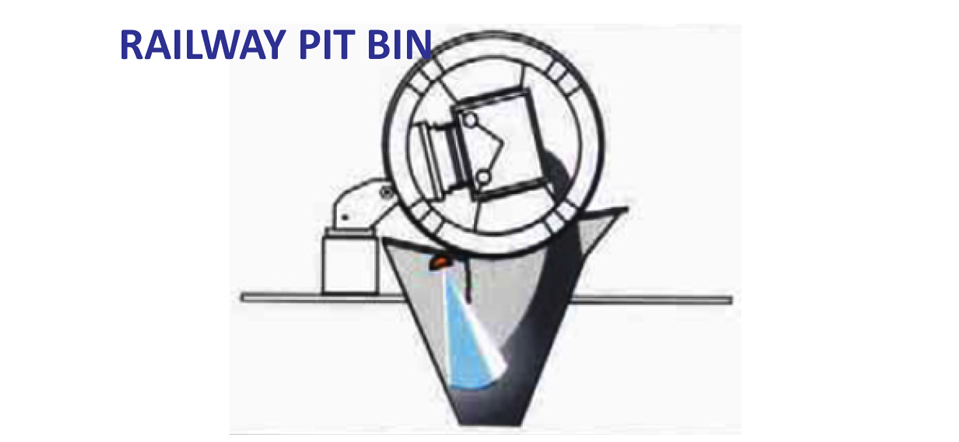

All stages of crushing and screening, truck dumps, storage bins, reclaimers, feeders, and rail car loading and unloading.

Smelting

Ore and cold slag handling.

Power

Solid fuel receiving, conveying, stacking, reclaiming, and processing.

All stages of crushing and screening, truck dumps, storage bins, reclaimers, feeders, stacking, limestone and additive storage silos and sheds.

All stages of crushing and screening, truck dumps, reclaim feeders, stacking and reclaiming.

Different Application Points

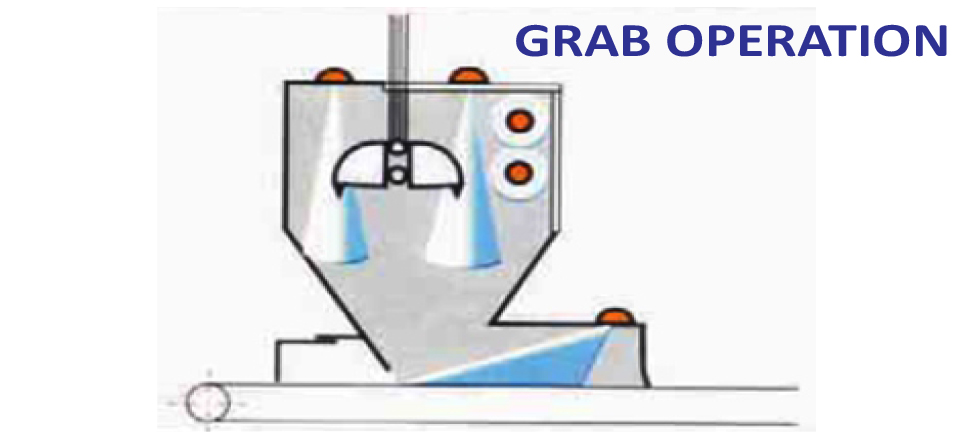

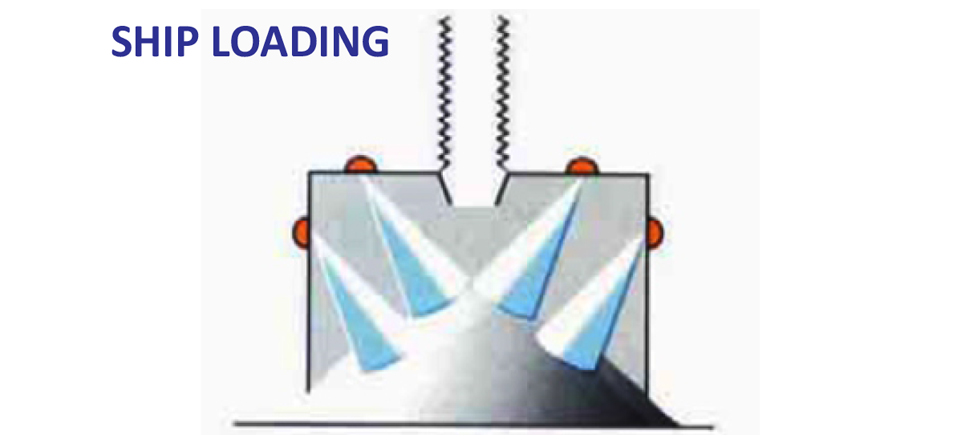

Wet fog systems have proven to significantly reduce fugitive dust from a variety of material handling points, including conveyor transfer points, trippers, reclaimers, crushers, screens, truck dumps, railcar loading / unloading, ship loaders-unloaders, and ash silo discharge chute.