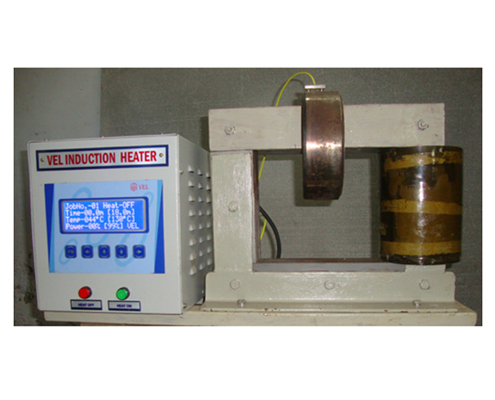

VEL BH Series

VEL BH series is a comprehensive range of Microcontroller based Electronic Control, Induction Heater, specifically designed and manufactured for mounting of shrink fitting components such as Bearings, inner races, gears, pinons, couplings, etc.

Standard Features

- Rugged and mobile construction

- Very Fast and efficient heating

- Heating of max bearing weights in less than 15 minutes

Our Machines Supplied

|

|

|

|

|

|

|

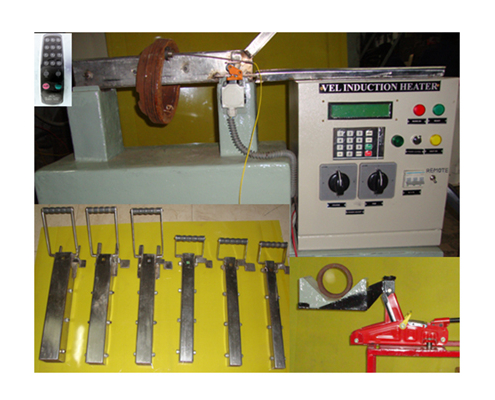

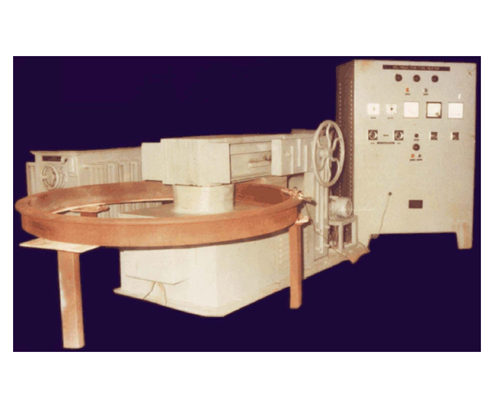

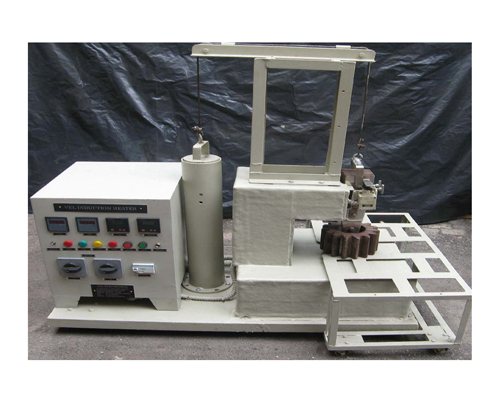

| Model No. | VEL/BH3 | VEL/BH8 | VEL/BH10 | VEL/BH13 | VEL/BH16 | VEL/BH25 |

| Technology | Microcontroller based Electronic Control, Induction Heater, specifically designed and manufactured for mounting of shrink fitting components such as Bearings, inner races, gears, pinons, couplings, etc. | |||||

| Bore Diameter Range | 20 to 300mm | 30 to 400mm | 70 to 600 mm | 100 to 1000mm | 55 to 600 mm | 100 to 1000mm |

| Max Bearing Weight | 40 kg (88 lb) | 120 kg (264 lb) | 300 kg (662 lb) | 1200 kg (2600 lb) | 300 kg (662 lb) | 1200 kg (2600 lb) |

| Coil & Yoke details | Single coil, horizontal swing arm yoke | Single coil, horizontal swing arm yoke | Single coil, vertical moving yoke | Single coil, vertical moving yoke (Motorized/ Manual) | Dual coil, horizontal rolling arm yoke | Dual coil, vertical moving yoke (Motorized/ Manual) |

| Job position axis | Vertical to the ground | Vertical to the ground | Vertical to the ground | Vertical to the ground | Horizontal to the ground | Vertical to the ground |

| Incoming Voltage | 230V, 1phase, 50Hz. | 415V, 50Hz, 3 Phase AC Supply | ||||

| Output Power | 2-3KVA | 6- 8KVA | 10- 12 KVA | 25 – 40 KVA | 14 – 16KVA | 25 – 40 kVA |

| Operational parameters | Time (0-99mins), Temperature (0 to 250°C, in step of 1°C), Power (0-100%) | |||||

| Temperature control | 25 – 250 +/- 1°C | |||||

| Memory Backup | To set & save all the operational parameters for different jobs (99 no. of jobs) in rewritable memory (EEPROM) of the microcontroller | |||||

| MMI | Man Machine Interface is 4-line alpha numeric LCD display. The LCD Displays all set, operational and trip parameters etc. Five functional keys to set & save the operational parameter | |||||

| Safety Interlocks | Soft start to avoid rush of surge current at time of switching

Over temperature of coil trip Current control & overload trip |

|||||

| Operating Area | 100 x 135 mm | 155 x 205 mm | 450 x 625 mm | 230 x 675 mm | 245 x 330 mm | 230 x 715 mm |

| Residual Magnetism | <2A/cm, Auto De – Magnetization | |||||

| Yoke size to suit bearing diameter | 14x14x215mm

28x28x215mm 45x45x215mm |

20 x 20 x350 mm

28 x 28 x 350 mm 45 x 45 x 350 mm 65 x 65 x 350 mm |

50 x 50mm

85 x 85mm |

70 x 70 mm

80 x 80mm 100 x 100mm |

40 x 40 x 500mm

60 x 60 x 500mm |

70 x 70 mm

80 x 80mm 100 x 100mm |

Note:

- We provide standard size of yoke as per industry standards. For any specific requirement, we also provide custom size yokes.

- For bearing weights more than 1200 kgs, we customize the product as per customer’s requirement and provide larger induction heaters.

- We also customize and manufacture bearing heaters as per client’s requirement.

Download Catalogue

| Accessories | Description & Features |

| Cooling System | 1) Refrigerant Chiller Unit 2) Cooling Tower with plate – type heat exchanger |

| Fixtures | 1) Mobile Hanging Assembly for Hand Held Transformer. 2) Manual / Motorized Rotary Fixtures (Horizontal / Vertical ) 3) XYZ Slide Fixture for Fixed Transformer |