Best Induction Brazing Machines for Copper Pipes in Mumbai, India

VEL Innovative Technologies offers high-performance induction brazing machines for copper pipes in Mumbai, India, designed to deliver precision, efficiency, and durability. Our VEL i-Braze series is ideal for industries requiring clean and consistent brazing solutions tailored for copper pipe applications. As a trusted name in the industry, we specialize in providing advanced induction brazing machines for copper pipes in Mumbai, India, ensuring superior results with robust and reliable engineering.

Whether for small-scale or large-scale operations, our machines are built to meet your specific needs. Experience the best in technology and performance with VEL Innovative Technologies’ induction brazing machines for copper pipes in Mumbai, India, crafted to enhance your production capabilities.

For More Information Pls Contact Us or Call Us +91 8104163453 or Email Us : mail@velinnovative.com sales@velinnovative.com

VEL i-Braze Series

VEL i-Braze series comprises of state-of-the-art induction brazing systems designed to meet the evolving demands in the field of metal joining.

It includes an advanced light weight and portable high frequency transformer and joint specific custom designed coils together known as brazing tong. The coils can be easily fitted on and removed from the transformer.

The brazing tong can seamlessly integrate with robotic arms or any automation as per client’s requirements

Related Services :

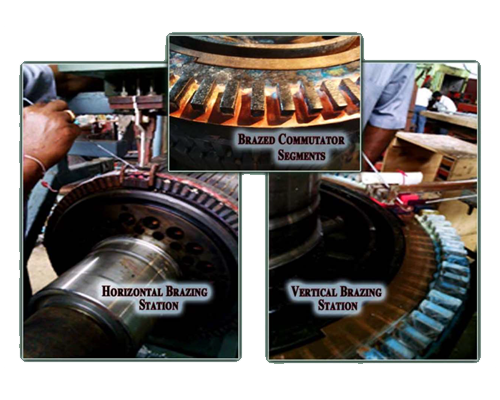

Induction Brazing Machine , Portable Induction Brazing Machine, Handheld Induction Brazing Machine, Induction Brazing Machine, Induction Brazing Machines, Rotor Brazing Machines.

Standard Features

- Application based customization

- Wide range of output power ratings and frequenciesrange

- Tolerates abrupt discontinuities in the coil circuit (e.g., sudden insertion, removal, or geometric changes

of the workpiece). - Withstands severe disturbances on incoming power lines.

- Integrates safety-oriented design features to prevent electric shock hazards associated with the brazing

tong during operation. - Features an automatic machine trip mechanism in the event of accidental contact between the brazing

tong and the workpiece, ensuring the integrity of both the machine and workpiece. - Safety Interlocks for Water pressure, temperature, flow, etc.

- Power Factor > 0.90

- Output regulation> 90%

- Intuitive user interface

- Simple and effective indications

Our Machines Supplied

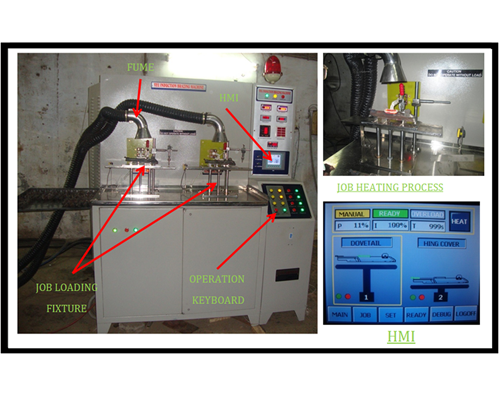

VEL i-Braze System (Type VEL/BR#) consists of ► Converter ► Inverter ► Micro controller based Control, Protection & Interlocks ► Output Transformer & Inductor ► Water Cooling & Circulating System (Optional) ► Holding Fixture (Optional) ► XYZ Slide for the Brazing Tong Assembly (Optional)

| Type : | VEL/BR20 | VEL/BR50 | VEL/BR80 | VEL/BR300 | |

| Inverter | IGBT based Inverter | ||||

| Converter | Thyristor based Full bridge Rectifier | ||||

| Incoming Voltage | 415 V/3ph /50 Hz, 3 or 4 wire | ||||

| Input Feeder Rating (A) | 40 | 100 | 160 | 600 | |

| Max Output Power (kW) (continuously variable 10-100% ) | 20 | 50 | 80 | 300 | |

| Output Frequency | 10 – 40 kHz | ||||

| Output Voltage (V) | 0-300 | 0-400 | 0-400 | 0-600 | |

| Coil Current(A) | 800 | 2000 | 3200 | 12000 | |

| Medium of Cooling | Air / Water | Water | Water | Water | |

| Brazing Tong | Compact water cooled transformer with flexible water cooled cable | ||||

Option 1:  Fixed Transformer |

Option 2:  Hand heldTransformer |

||||

Note: We also deliver customized solutions tailored to your application needs, offering flexibility in intermediate power rating, frequency, and automation levels

Download Catalogue

| Accessories | Description & Features |

| Cooling System | 1) Refrigerant Chiller Unit 2) Cooling Tower with plate – type heat exchanger |

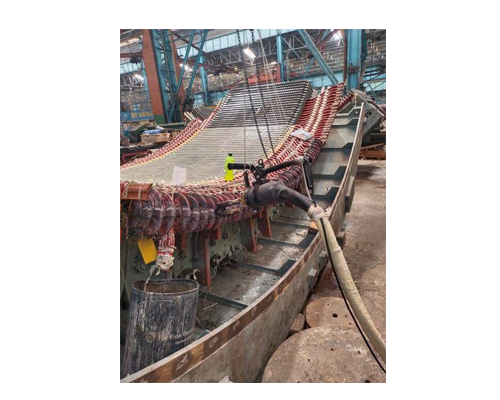

| Fixtures | 1) Mobile Hanging Assembly for Hand Held Transformer. 2) Manual / Motorized Rotary Fixtures (Horizontal / Vertical ) 3) XYZ Slide Fixture for Fixed Transformer |