Expert Induction Hardening Job Work in Mumbai, India – VEL Innovative Technologies Pvt Lt

Welcome to VEL Innovative Technologies Pvt Ltd, your trusted partner forinduction hardening job work in Mumbai, India. We specialize in providing precision induction hardening services that enhance the strength, durability, and wear resistance of your metal parts. With cutting-edge technology and skilled professionals, we deliver high-quality hardening solutions tailored to meet the unique requirements of your projects. If you’re looking for reliableinduction hardening job work in Mumbai, India, VEL Innovative Technologies offers cost-effective, efficient, and industry-leading services to help your components perform at their best. Get in touch with us today to learn how our expertise can elevate your manufacturing processes.

For More Information Pls Contact Us or Call Us +91 8104163453 or Email Us : mail@velinnovative.com sales@velinnovative.com

What is Hardening with Induction?

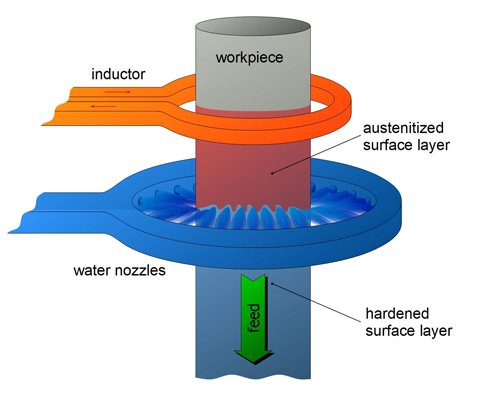

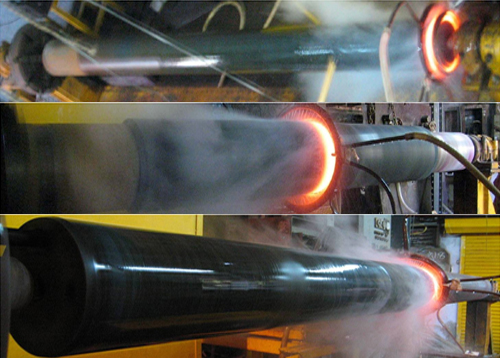

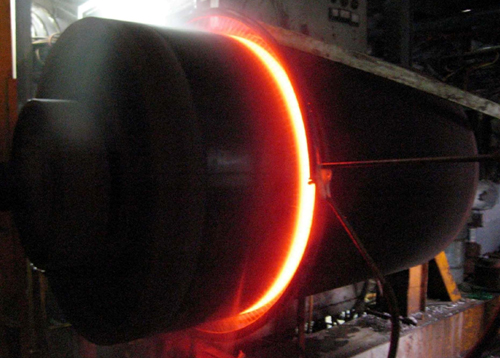

Induction hardening is a specialized heat treatment method used primarily for metal parts containing sufficient carbon content. This process involves heating the metal part within an induction field and then rapidly cooling it. The purpose is to enhance both the hardness and brittleness of the part, improving its resistance to wear while maintaining its overall mechanical properties.

The key advantage of induction heating lies in its ability to provide localized heating to a precise temperature, allowing for accurate control over the hardening process. This level of control ensures consistent results and process repeatability, a critical factor in industrial applications.

Why choose VEL for your Induction Hardening Job Work needs?

VEL excels in providing precise control and reproducibility of hardening outcomes for individual components. Through customized adjustments in inductance, energy, frequency, quenching, and annealing steps tailored to each workpiece, VEL ensures optimal treatment, even for intricately shaped components. This results in top-notch hardness, meeting stringent quality standards for durable, high-performance parts.

A well-planned Induction Hardening setup considers material resistivity, permeability, part geometry, mass, and required heating rate. Parameters such as power rating, output head configuration, power density, and overall efficiency are carefully chosen to meet specific heating needs, reflecting VEL’s commitment to excellence in Induction Hardening in India.

Related Services:

Induction Hardening Services, Induction Hardening Job Work, Heat Treating Services

Induction Hardening Job Work we provide

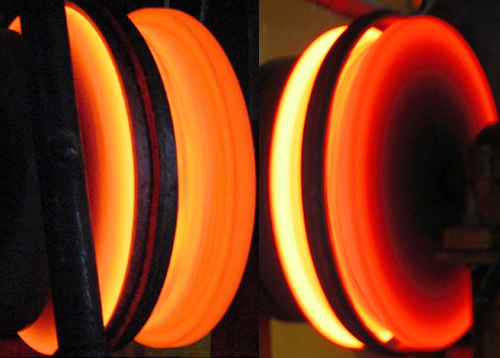

Induction Hardening of Groove Rings

Slue Ring, Revolving Joint, V- Pulley, Bearing Race, Rope Drum, Flat Pulley, Bearing Collar, Flange, etc.

Diameter : 25-100 mm ® Hardness : 40-56 HRC, Case Depth : 1.5-3 mm.

Diameter : 400-3000 mm® Hardness ;40-56 HRC, Case Depth :2-5 mm.

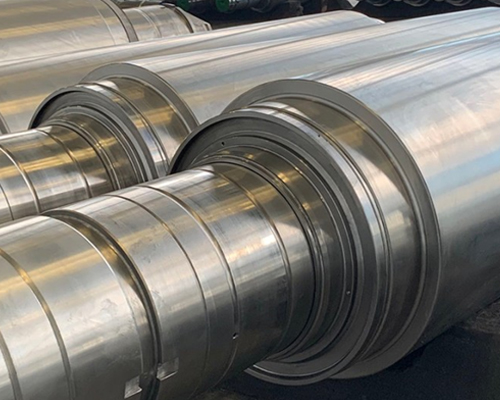

Induction Hardening Rolls

Backup Roll, Guide Roll, Pinch Roll, Deflector Roll, Bridle Roll,Work Roll, Cradle Roll, Thrust Roll, Leveler Roll, Slitter Roll, Track Roller,Track Roller Shaft, etc. for Steel mills, Plastic Industries, Textile Industries, Paper Industries, Process Industries, Rolling Mill, etc.

Diameter : 30-120mm, Hardness : 58-62 HRc, Case Depth : 0.5-3 mm

Diameter : 100-1400mm, Hardness : 58-62 HRc, Case Depth : 5-10 mm

Diameter : 300-1200mm, Hardness : 58-62 HRc, Case Depth : 8-40 mm

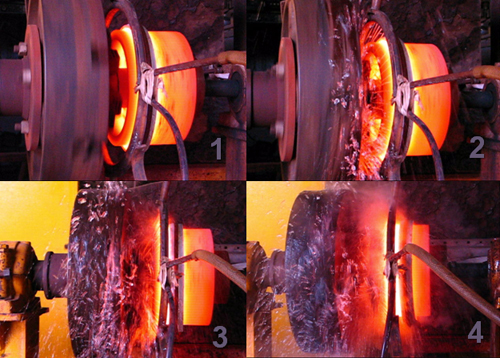

Induction Hardening of Wheels

Crane Wheel, Trolley Wheel etc.

Diameter : 160-900 mm ® Hardness: 40-55 HRc, Case Depth : 5-10 mm.

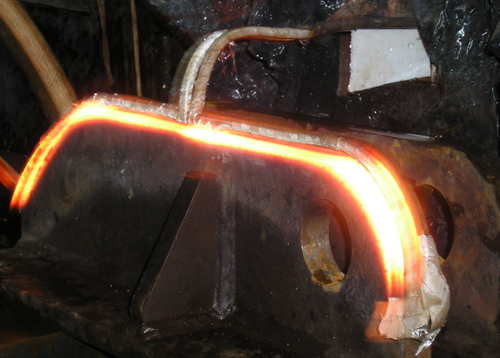

Induction Hardening of Automobile components

Fork.Selector, Camshaft, Crankshaft. Rear Axle Shaft, Front Wheel Spindle Shaft,Spline Shaft, Transmission Shaft, Shifter Fork, Rocker Arm,Rocker Pad. Various Transmission Gear, Hand Piece, Differential Housing, Cylinder Head, Pump Shaft. King Pin, Universal Joint Push Rod, Starter Gear Ring, Gudgeon Pin, Valve Seat,Taper Lever, Screw Ball, Rotor Spindle etc.

Any desired hardness pattern could be achieved.

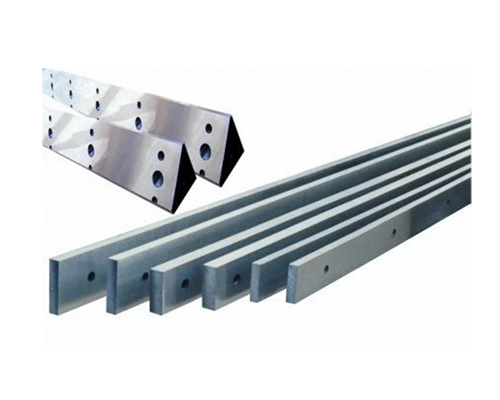

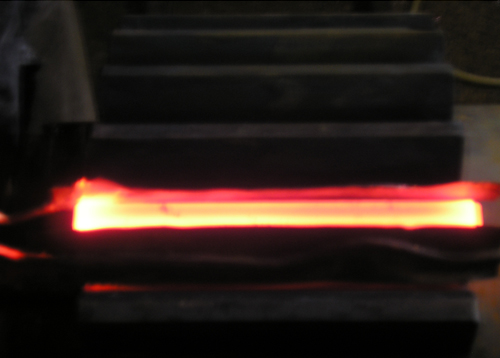

Induction Hardening of Die

Forming Die,LinerGuide Way,Machine Column,Lathe Bed,Machine Bed,Lead Screw,Ball Screw, Rail, V-Punch, Shear Blade, Liber, Crimping Die, Track Liner, Wedge,Expander tool, etc.

Face Width : 40-600 mm ® Hardness : 35-45HRc; Case Depth : 3-4mm

Induction Hardening of Brake Drum

Diameter : 100-600 mmmm® Hardness : 35-45HRc; Case Depth : 3-5mm

Induction Hardening of Sprockets

Sprocket for Chain Conveyor, Bucket Elevator, Transmission Line etc.

Diameter : 100-1500 mm; Thickness : 4-160 mm; Roller Diameter : 6-100 mm ® Hardness : 50-60 HRc, Case Depth : 1.5-10 m (Root Hardening).

Induction Hardening of Gears

Spur Gear, Helical Gear, Bevel Gear, Rack, Pinion, Worm Gear, Worm Ring Gear,Shaft, Gear Casing, Gear Coupling, Infernal Gear External Gear etc.

Diameter : 10-100 mm, Thickness : 5-20mm; Module 1-10mm ® Hardness : 45-62 HRC, Case Depth: 1 -3 mm.

Diameter : 100-1500 mm, Thickness/Face Width : 20-600 mm, Module : 10-100mm ® Hardness : 45-62 HRc, Case Depth : 3- 10mm, (Root/Crest Hardening)

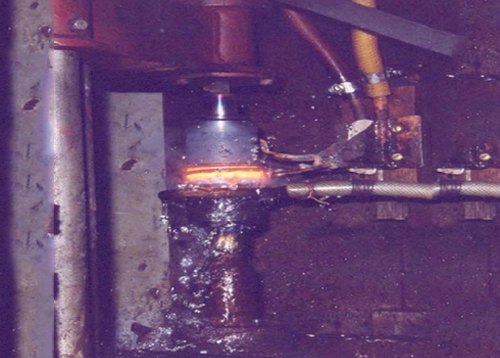

Shafts Hardening

Axle Shaft, Cam Shaft. Spline Shaft, Piston Rod, Pin, Flute, Tube, Pipe etc.

Diameter : 2-20 mm -> Hardness : 50-62 HRC, Case Depth : 0.5-3 mm.

Diameter : 20-200 mm -> Hardness : 50-62 HRC, Case Depth : 3-10 mm.

Diameter : 200-2000 mm -> Hardness : 50-56 HRC, Case Depth : 5-25 mm.

Tools / Fasteners / Grease FittingsInduction Hardening Services

Lead screw, Chisel, Bolt Head, Hammer Head, File, Hacksaw Blade,Letter Punch, Rock Drill, Cutter, long, Pliers, Tip of Screw Driver,Link,Hook, Eye Bolt, Track Link, Track Pin,Track Shoe Bolt, Nut,Screw, Wrench, Spanner, Knife, Hopper, Type writer Key, Grease Nipples, Straight Grease Fitting, etc.Any desired hardness pattern could be achieved.